Profit from our more than 40 years of experience

We use standardised project plans when designing and producing hydraulic cylinders specially designed for a customer application. They are flexibly adapted to the respective requirements. This ensures that the project is completed on schedule – at the same time, this process offers the security that nothing is forgotten.

Using the latest CAD software such as the OneSpace-Designer, the cylinders are designed three-dimensionally.

These models form the basis for the subsequent process steps:

- Collision Analysis

- Strength verification according to customer requirements

- Enquiries to partner companies

- Determination of the production sequence

- Generation of CNC programs

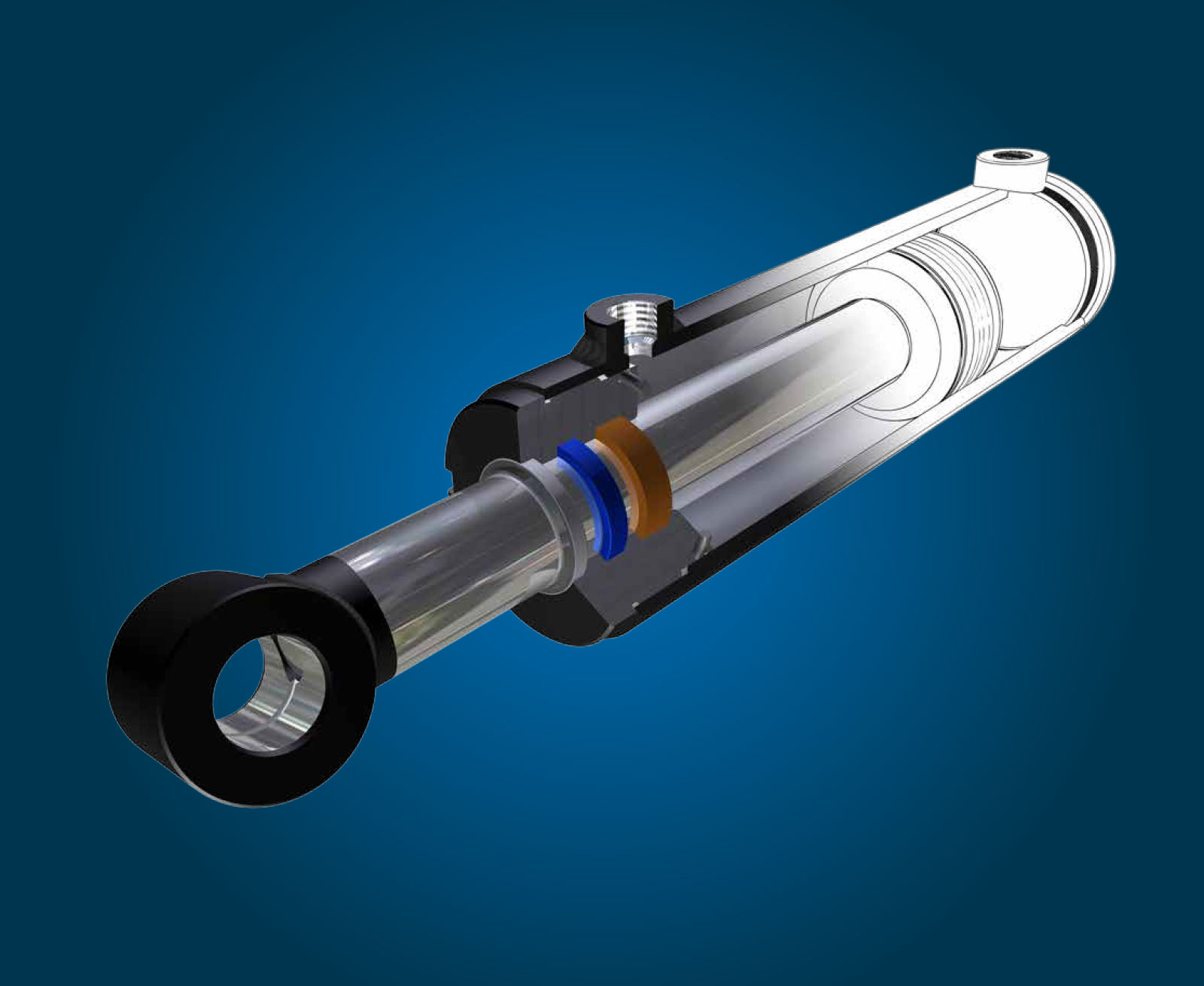

The load cases required in our customer’s project form the basis on which we calculate the cylinder tube and piston rod according to 1st and 2nd order theory.

Furthermore, threads, weld seams, seals and guide tapes are designed according to applicable standards.

We incorporate the resulting results into the design model of the hydraulic cylinder. In order to take into account complex mechanical problems of the cylinder, we additionally examine it using the finite element method. This procedure is carried out by external civil engineers.